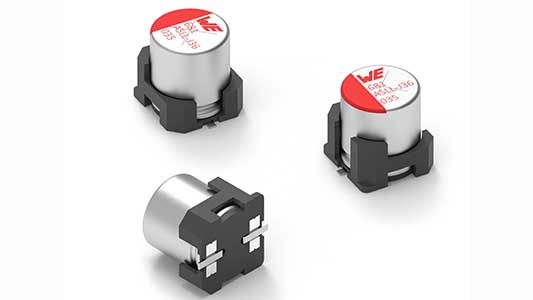

Waldenburg (Germany) – All SMT variants of the Aluminum Electrolyte and Aluminum Hybrid Polymer capacitors from Würth Elektronik are now available in an extremely vibration-resistant version on request. Thanks to their enlarged solder pads and thicker base plate, the capacitors can withstand acceleration up to 30 g (294 m/s²).

Electronics must continue to function reliably, even when exposed to strong mechanical stresses. This is the case with electronically controlled tools, industrial applications, construction machinery, or drones, for example.

Risk of failure during continuous operation

SMT components are often not the best choice here, because without special adaptations, they may not withstand the prolonged vibration stress. Especially larger components then quickly reach their limits. Under continuous load, they can detach from the circuit board and cause the electronics to fail.

Optimized for tough operating conditions

However, making electronics vibration-resistant does not necessarily require special connection techniques like press-fitting. The vibration-resistant versions of the Würth Elektronik capacitors feature larger solder pads for a more stable connection to the circuit board and an extra-high base for improved support and vibration damping. In order to maintain optimal temperature management, the well-known manufacturer of electronic and electromechanical components has provided the base of these capacitors with special cut-outs.

Quality assurance in twelve-hour endurance test

The capacitors are tested under conditions that go beyond the requirements of IEC 60384-4: The components must remain securely attached to the circuit board for twelve hours (four hours per axis) under vibration in the frequency range between 10 Hz and 2 kHz with an amplitude of 0.75 mm. The final electrical tests then confirm their functionality.

The vibration-resistant capacitors can be processed on standard SMT production lines. They are delivered with the desired specifications on request.