Some customers only pay attention to several important parameters such as power, output voltage, and efficiency when choosing a switching power supply, and complete the selection in a hurry. Finally, because some details were ignored, the power supply failed not long after it was turned on.

For example, the indoor environment of the factory building is not exposed to the sun and rain, but it is full of metal dust; Another example, the application environment of beauty-care and teaching equipment is good, but they have high requirements for noise; the equipment in the suburbs is powered by the power grid, and the harmonic interference in the power grid is high, etc… In the face of these special factors, it is very risky to choose a conventional switching power supply, and the power failure rate is also increased.

In this article, we will talk about how many hidden risks in these details we often ignored, and how to avoid these “fatal risks” from the initial selection of power supply.

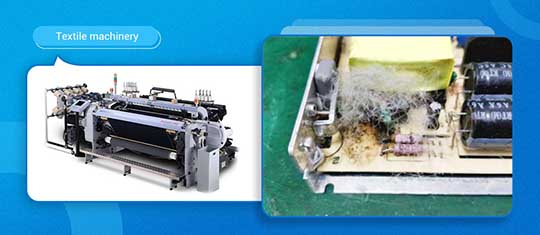

1. Indoor Environment- Textile Machinery

Cotton fiber is most troublesome in the textile machinery industry. As shown in the picture below, the cotton fiber will inevitably float to all corners. The high-power power supply is usually built-in a fan, which is easy to roll the surrounding cotton fiber into and causes failure.

Pain point 1: Two cases of failures, one is the cotton fiber getting stuck in the fan that causing the failure of the power supply as the fan was damaged and cannot dissipate heat; The other one is the metal pins of high-voltage components (high-voltage capacitors, semiconductors) that exposed to outside, if the product sparks abnormally, there is a risk of igniting cotton fiber and causing a fire.

Solution: The LMF-23BxxUH series adopts a fanless design, so there is no need to worry about the fan being damaged and causing the equipment to be abnormal; the product also adopts the semi-potted design and effectively avoids exposure because the pins of the high-voltage components are all potted.

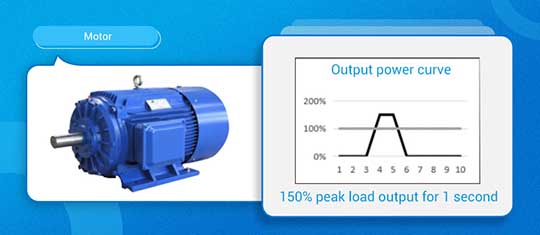

Pain point 2: Textile machinery has a motor-type load, which requires high power to transient start, and only requires less power to maintain operation after the startup. Many power supplies trigger overpowering protection due to excessive output power during the startup, resulting in the startup failure of the equipment and unable to work normally.

Solution: The LMF-23BxxUH series features “150% peak load output for 1 second” to ensure the startup of the equipment normally and meets the motor application requirement.

2. Outdoor Environment- DC Charging Station

Most of the charging stations are installed outdoors with large temperature differences, which is a high temperature/high humidity/dusty environment.

Pain point 1: The outdoor environment is always windy and rainy, and high humidity, which will easily damage the SMD components on the PCB, resulting in the power supply abnormally and the equipment cannot work normally.

Solution: LMF-23BxxUH products adopt the potting design for the SMD components in PCB, so there is no need to worry about dust and moisture. At the same time, MORNSUN has improved the production process and strengthened the product’s corrosion resistance performance.

Pain point 2: In harsh environments such as remote regions or highways, the voltage fluctuation of the power grid would be great, especially at night, the voltage is easy to exceed the input voltage limitation (264Vac) of the mainstream power supply, resulting in over-voltage damage to internal components. At the same time, lightning strikes will happen outdoors, and the lightning surges are easy to damage the power supply, which requires the power supply to feature high reliability and good EMS performance.

Solution: LMF-23BxxUH series is the product in MORNSUN 305RAC collection, it features a wide input voltage range up to 305VAC, is Reliable under all conditions, and has excellent EMS performance, such as EFT meets IEC/EN 61000-4-4 ±4KV, and the Surge meets IEC/EN 61000-4-5 line to line ±2KV/line to ground ±4KV.

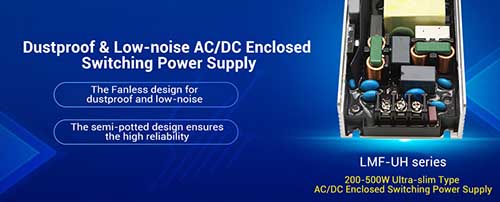

3. Selection of Enclosed Switching Power Supply: For the targeted applications

The LMF-UH series provides one more choice of power supply solutions for customers, which can solve the problems of dust, noise, humidity, dimension, etc., It also complies with various certifications, and has advantages for applications in high-altitude. At present, the wide power range of the LMF-UH series covers 200 -500W.

The LMF-UH series is a “dustproof & low-noise AC/DC enclosed switching power supply”, but this does not mean that the LMF-UH series is “suitable for all applications”. In different application environments, the power supply of the equipment may face different working conditions that most of which are lossy factors, such as power grid fluctuations, electromagnetic interference, metal dust, humidity, salt spray corrosive gases, temperature differences, and so on.

For different working conditions and pain points in different industries, Mornsun can provide the most suitable products from our enclosed switching power supplies.

For example, if there is no requirement for dimension and used in the general indoor environment, we would like to suggest choosing the 264V input products; if it is applied at the seaside or in an environment with large salt fog, or if in the suburbs with great power grid fluctuation, we would like to suggest choosing the 305RAC products; if for some communication industries or other industries require fanless, we would like to suggest choosing the fanless semi-potted AC/DC enclosed power supplies (LMF-UH series).

The power supply is the core of the equipment. Choosing the right power supply not only saves maintenance costs in the subsequent period but also helps to improve the reliability of equipment. It is the key to selecting the appropriate and reliable products for different application scenarios.