Integrated circuit or microchip are semiconductors. Semiconductor conducts electricity within two materials and insulates the other two. Semiconductors are useful in electronics because they conduct and insulate.

Did You Know:

In the year 2019, about 300 billion chips were sold worldwide. On average, each individual on the earth would have 40 chips.

Most electronics nowadays use semiconductors. Medical equipment, watches, mobiles, PCs, and laptops are typical gadgets. Semiconductors make electronics quicker, more efficient, and cheaper.

Supply-chain breakdowns and semiconductor chip shortages have been in the headlines for months. Now, even folks who didn’t know about semiconductor production concerns undoubtedly do. Knowing or comprehending the difficulties isn’t enough; action is needed. These are some manufacturing hurdles.

KEY POINTS

- India could have a large role to play in the semiconductor industry, analysts say.

- India has been making moves to bring the manufacturing of chips to the country.

- New Delhi’s strategy is twofold — lure in foreign companies and build on areas where India has an advantage, such as chip design.

Time, resources for new factories

Some question why additional semiconductor factories can’t be built. The world’s fifth-largest economy might play a big role in the semiconductor business, economists believe.

India, like the U.S., is seeking strategic partnerships around semiconductors, a key technology in cellphones and refrigerators. India’s capabilities might help it become a chipmaking centre.

“As the second-most populated country in the world, India has a significant domestic semiconductor market,”

The India context:

The Indian government has launched a 76,000 crore (>10 billion USD) effort to boost the semiconductors and display manufacturing ecosystem. The initiative includes plans to encourage investments in semiconductors and display manufacture. This includes pari-passu financial assistance for Semiconductor Fabs in India. India Semiconductor Mission was created to establish a sustainable semiconductor and display ecosystem.

Several global and local corporations have shown interest in establishing Fabs/Foundries and Packaging Units in response to government incentives and initiatives. This is optimistic for the Indian industry and economy and India’s desire to become a “Semiconductor Nation,” but semiconductor production must involve a significant emphasis on sustainability and ESG.

Reducing semiconductor manufacturing’s environmental effect will need new technologies and creativity throughout the value chain. Innovations in process, sustainable materials, optimizing resource utilization (power, water), hazardous waste disposal, recycling, reuse, and industry 4.0 may help India embrace sustainable semiconductor manufacturing techniques.

“Everyone in the semiconductor and IT industries would benefit from increased diversity”.

The Indian semiconductor market is anticipated to increase by $400 billion by 2025. This is due to the fact that the demand for semiconductor products is growing every day.

The availability of talent and expanding demand are the two key drivers of the semiconductor industry’s expansion. The Indian Semiconductor Association estimates that between 2015 and 2020, the semiconductor market would grow at a CAGR of 29.4%.

Future demand for semiconductors will be sustained as the Internet of Things (IoT) idea gains momentum. According to estimates from the Department of Electronics and Information Technology (DeitY), India develops around 2000 chips annually.

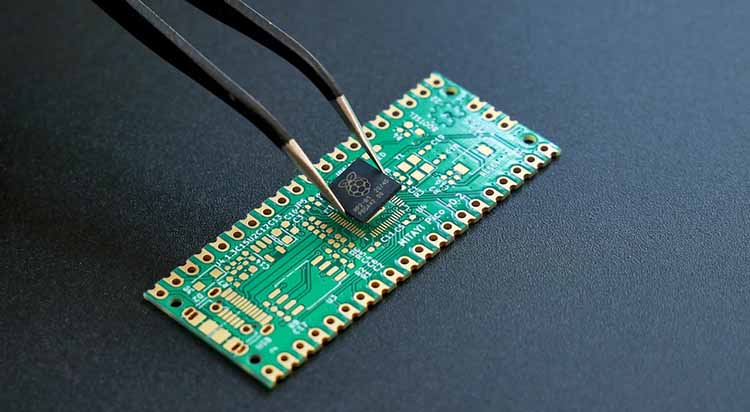

Semiconductor Chips

- About: Semiconductors are substances whose conductivity is between that of conductors and insulators. They may consist of pure elements, such as silicon or germanium, or compounds, such as gallium, arsenide, or cadmium selenide.

- Significance of Semiconductor Chips: They’re the heart and brain of contemporary electronics and ICT good. These chips are now in modern cars, home electronics, and ECG equipment.

- Recent Increase in Demand: The Covid-19 pandemic-driven effort to digitize large areas of everyday economic and critical activity has underlined the significance of chip-powered computers and cellphones in people’s life.

- The epidemic and lockdowns led chip-making factories in Japan, South Korea, China, and the US to shut.

- Its scarcity generates cascading consequences, since the first builds pent-up demand that triggers the next famine.

- India’s Semiconductor Demand and Related Initiatives: India now imports all of its chips, and by 2025, the market is expected to grow to $100 billion from its current $24 billion value.

- The Union Cabinet has approved spending $76,000 crore to help the creation of an “environment for semiconductor and display production.”

- The strategic importance of integrated circuits, or chips, to a contemporary economy is now being acknowledged, which is good.

- India has also begun promoting the production of electronic components and semiconductors via the Scheme for Promotion of Manufacturing of Electronic Components and Semiconductors (SPECS), which will spend Rs 3,285 crore over the course of eight years.

- Challenges Associated

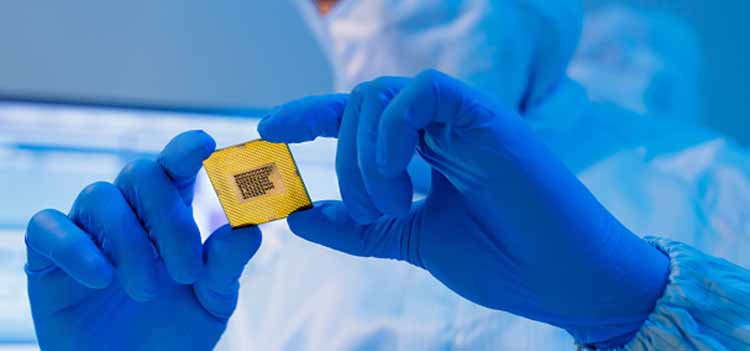

- High Investments Required: Manufacturing of semiconductors and displays is an extremely complicated and technologically advanced industry that requires considerable and persistent expenditures because to its high capital costs, high risk, lengthy gestation and payback times, and fast technological development.

- Minimal Fiscal Support from Government: When one considers the size of investments normally necessary to build up production capabilities in the different sub sectors of the semiconductor industry, the amount of fiscal assistance now envisaged is negligible.

- Lack of Fab Capacities: Although India lacks chip fabrication capability, it has some competent chip design skills. Both the ISRO and the DRDO have their own fabrication facilities, however they are mostly used for internal needs and are not the most advanced in the world.

- Extremely Expensive Fab Setup: Even on a relatively modest scale, setting up a semiconductor production facility (or fab) may cost multiples of a billion dollars, and it behind the most recent technological advancements by one or two generations.

- Insufficient Grants under PLI Scheme: Despite the fact that India’s Production Linked Incentive (PLI) scheme intends to provide only 50% of the cost of setting up at least two greenfield

- semiconductor fabs through fiscal support, not much of the current scheme outlay (roughly $10 billion) is likely to be left to support other elements such as display fabs, packaging and testing facilities, and chip design centers.

- Resource Inefficient Sector:Additionally, chip factories are exceedingly thirsty, needing vast amounts of pure water, a highly reliable power source, a large amount of land, and a highly qualified crew.

- Way Forward

- Sufficient Fiscal Support for All the Elements: It could be preferable if the new mission concentrates financial assistance, at least initially, on other aspects of the chip-making chain, such as design centers, testing facilities, packaging, etc., given India’s vast expertise and experience.

- Maximising Self-Reliance: In the future, making chips shouldn’t be a one-trick pony. Instead, they should be part of an ecosystem that includes design, fabrication, packaging, and testing. India also needs to improve its research and development in this area, which is not as good as it could be.

- Out-strategising Designs and Functionalities: Due to the long gestation periods and fast changes in technology, India must out-strategize on design and functionality. The end product won’t be ready for three or four years after work starts, by which time the chip shortage will be over and technology will have moved on.

- Role of Public Sector Enterprises (PSEs): With the aid of a multinational corporation, Indian PSEs like Bharat Electronics Ltd. and Hindustan Aeronautics Ltd. might be utilised to establish a semiconductor fab foundry. Giving management in a joint venture where the global major has contributed technological competence full reign and offering them long-term policy stability coupled with the right incentives might very well result in success.

- Connectivity and Capability Related Measures: India needs several variables to succeed in chip production and design. The Indian government must link chip-related industries to establish an ecosystem. Improve national competency. Emerging enterprises should be able to survive without government support.

- Leveraging Groupings such as Quad: India needs global collaboration to develop important and emerging technologies. The Quad Semiconductor Supply Chain Initiative helps. India needs a Quad Supply Chain Resilience Fund to protect against geopolitical and geographic hazards.

Future of Semiconductor Industry in India

Manufacturing, design, and R&D for semiconductors are areas in which India aspires to excel. Semiconductor sales in the nation are expected to reach $80 million by 2026. Data also shows that by 2030’s end, the market would have expanded by USD 110 million.

There is a wide variety of enterprises in the Indian semiconductor sector, some of which may be classified as fabless firms and others as foundries. Fictional companies put a premium on the design of semiconductors. In contrast, semiconductor foundries place a premium on quality control.

Setting-up a Semiconductor facility in India.

A Long Term Plan – Due to the significant capital requirements, foundry establishment requires a sound long-term strategy and enough funding. Both the government and the entrepreneur must provide this support.

Fiscal Sustenance – The Indian government will play a significant role in supporting the Fab and the semiconductor sector in India via tax holidays, subsidies, zero-duty policies, financial investments, etc. This would increase pressure on the country’s already significant fiscal deficit. It need a strong financial system to get the desired result.

Support Infrastructure – To ensure the smooth operation of the Fab, this is a crucial factor that must be taken into consideration. Fast transportation, a vast supply of clean water, consistent energy, communication, a pollutant-free environment, and other necessities of a contemporary Fab should be given by a world-class, sustainable infrastructure.

Government Policy – One of the most crucial elements for such a significant move to be made is this. Regardless of whose party is in power, the policy adopted today must be legitimate and stable for at least 10 to 15 years and contain all types of subsidies that may be reduced in the future with the appropriate conditional provisions.

Obstacles & Challenges.

- Huge Investments involved

- Semiconductor Fabrication is a volume production facility rite from the starting.

- Semiconductor Fabrication will require cheap but skilled labor.

- Very High end world –class machinery involved.

- Requirement of very specific raw materials.

- Uncertain Indian market

- Customer requirements are changing, and change the electronics inside.

Disposable of Hazardous Waste

Conclusion

India has come to the conclusion that it would be unwise to pursue a strategy that would have it completely reliant on global supply networks for something as essential as semiconductor chips. A step in the right direction was taken when the Cabinet made the decision to simultaneously establish an India Semiconductor Mission. This mission will be led by ‘global industry experts’ and will be responsible for driving long-term strategies for the sustainable development of the chip and display industry. Analysts believe that the move, which is taking place at a time when the entire world is experiencing a shortage of semiconductors, could go a long way toward establishing the country as a global hub for the production of electronics goods. In addition to creating jobs and attracting investments from top companies around the world, the move would also have the additional benefit of establishing the country as a global leader in the production of electronic goods.